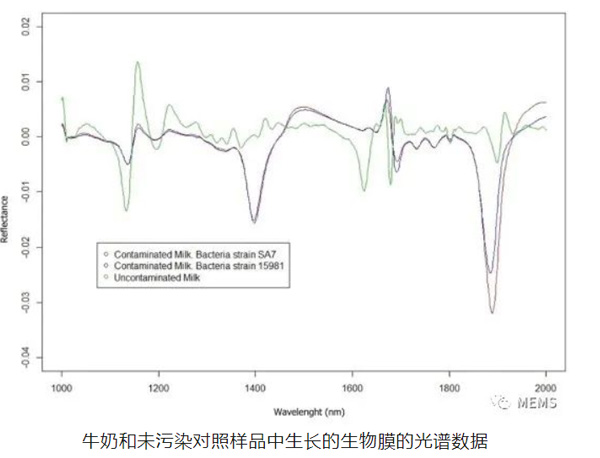

Near-Infrared (NIR) spectroscopic analysis is a technique that utilizes light in the near-infrared wavelength range to determine the physical, chemical, or structural properties of materials. Infrared spectroscopy covers the spectral region from 780 to 2500 nm, measuring the interaction between infrared radiation and substances through absorption, emission, or reflection. This technology has proven its reliability in detecting and quantifying microorganisms, becoming a non-destructive alternative in molecular biology techniques. It is considered an efficient and rapid method for identifying bacterial contamination in milk.

This study aimed to assess the capability of near-infrared spectroscopy in detecting bacterial contamination in milk. To analyze the near-infrared spectroscopy data in this study, researchers slected a combination of Principal Component Analysis (PCA) and Partial Least Squares Discriminant Analysis (PLS-DA) to address the challenges posed by high-dimensional spectral data. The goal was to reduce dimensions, extract informative features, and enhance the effectiveness of sample classification. The results indicated that this technique could effectively differentiate between contaminated and uncontaminated samples, with an Area Under the Receiver Operating Characteristic Curve (AUC) exceeding 99%. The method also demonstrated effectiveness in classifying samples of different bacterial strains.

Researchers emphasized that using near-infrared spectroscopy is a promising non-destructive method for detecting bacterial contamination in milk. The spectroscopic instruments and data processing methods employed in this study can qualitatively identify bacterial contamination by analyzing changes in spectral patterns, distinguishing between contaminated and control samples.

In summary, rapid and non-invasive bacterial detection is a crucial goal in the dairy industry. Traditional methods for detecting bacteria in milk are time-consuming and require skilled personnel. Near-infrared spectroscopy can provide real-time and accurate results without the need for sample preparation or destruction. Additionally, compared to traditional bacterial detection methods, it can reduce time and costs. However, before widespread industrial application of bacterial detection , further research is needed to optimize and validate the accuracy of this technology on a large scale. It is also necessary to consider the possibility of errors or distortions in sample spectral records and review the collection schemes to improve the accuracy of the models.