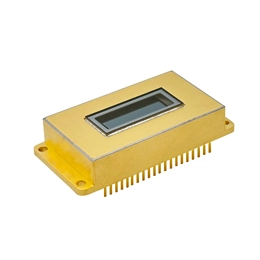

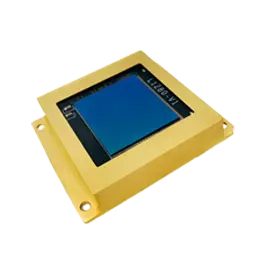

Machine vision, as the name suggests, is to give machines vision, which is the science and technology of using computers to simulate biological (external or macro) visual functions. It integrates multiple fields such as optics, mechatronics, computer software, signal processing, and opto-mechanical and electrical integration. Here is an introduction to the three main functions of machine vision: positioning function, measurement function, and defect detection function. The technology of ingaas linear image sensor also adopts the machine vision.

It can automatically determine the position of the object and output the position information through a certain communication protocol.

This is a more commonly used function of machine vision, which can detect some information on the surface of an object. For example, whether the packaging is correct or not, whether the surface of the object is scratched or particles, damaged, oily or dusty, etc., basically can be judged by the human eye, you can try to replace it with visual technology.

It can automatically measure the appearance and dimensions of the product, such as contour, aperture, height and area.

The principle of the measurement function:

Imaging the sensing product or area, and then processing it with special image processing software based on its image information. According to the processing result, the software can automatically determine the product's position, size, and appearance information, and set it in advance according to humans. The standard is used to judge whether it is qualified or not, and the judgment information is output to the executive agency. The infrared zoom lens system uses a CCD camera or a sensor CMOS camera to convert the detected target into an image signal, which is sent to a dedicated image processing system. According to the pixel distribution, brightness, color and other information, it is converted into a digital signal. The image processing system performs processing on these signals. Various operations to extract the characteristics of the target, such as area, number, location, length, and then output the results according to the preset allowability and other conditions, including size, angle, number, pass/fail and yes/no, to achieve automatic recognition function.

In the production process of the product and the quality inspection after the product is completed, size measurement is an indispensable step, and machine vision has its unique technical advantages in size measurement: it can save a lot of labor resources and bring considerable benefits to the company, so its application is becoming more and more extensive. The size measurement of machine vision is basically non-contact measurement. This non-contact measurement method can avoid damage to the measured object and is suitable for situations where the measured object is inaccessible, such as high temperature, high pressure, fluid, and environmental hazards; At the same time, the machine vision system can measure multiple sizes at the same time, which realizes rapid batch measurement and is suitable for online measurement; and the measurement of small sizes is the strength of the machine vision system. It can use a high-power lens to magnify the measured object, making the measurement accuracy above micrometers.

To sum up, compared with manual or traditional mechanical methods, machine vision systems have a series of advantages such as fast speed, high precision, and high accuracy. With the development of china ir photodiode sensor industrial modernization, machine vision has been widely used in various fields to provide enterprises and users with better product quality and perfect solutions.