With the advent of the industrial era, the application of machine vision systems in the field of intelligent manufacturing is becoming more and more extensive. Cameras are an important component of machine vision, and choosing the right industrial camera is crucial to the performance of the system. This article mainly introduces how to choose the right industrial camera.

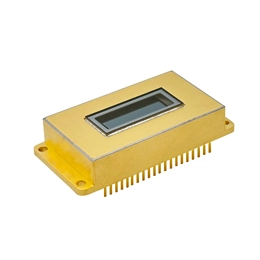

Industrial cameras are a key component of machine vision systems, whose essence is to convert light signals into ordered electrical signals, acting as the "eyes" of the machine vision system. Compared with traditional consumer cameras, industrial cameras have high image stability, high transmission capacity, and high resistance to interference, most of which are based on CCD or CMOS chips.

In product development and verification. For example, when developing metal and resin materials, it can be used to observe the direction and status of internal cracks produced by the material under impact, analyze the structure of the material when it is destroyed, and for industrial online inspection of electronic products, etc.

In the packaging and label industry's printing process. In the printing process of the packaging and label industry, it can detect micro-defects in high-speed printing in real-time to reduce losses. Common defects such as scratches, dust, missed printing, ink marks, and wrinkles can all be detected, improving investment return, reducing waste, and enhancing customer satisfaction and trust.

In other fields, such as machine vision, scientific research, military science, aerospace, and many other fields, especially in the field of intelligent transportation: speeding capture, running a red light electronic police, highway intersections, toll gates, etc.

Choosing the right camera is an important part of machine vision system design, and the choice of camera not only directly determines the image resolution, image quality, etc. but is also directly related to the operation mode of the entire system.

Camera type

For static detection or general low-speed detection, matrix cameras should be prioritized, and for large-area, high-speed motion, or scrolling applications, line-scan cameras should be selected. According to the detection speed, the frame rate of the industrial camera must be greater than the speed of the object, and it must be completed within the exposure and transmission time of the camera. In actual detection, there are multiple solutions to achieve the same purpose, leaving more options for camera selection.

Camera frame rate

The frame rate of the camera determines the efficiency of the device. For example, if the frame rate of the camera is 30FPS, it can capture up to 30 times per second. Generally speaking, the lower the resolution of the camera, the higher the frame rate will be for the same interface, and the higher the resolution, the lower the frame rate will be. When the interface is fixed (the total bandwidth is determined) and the resolution is constant, the frame rate also has its maximum value. If you want a faster camera resolution and a higher frame rate, you need to find a larger bandwidth interface.

Camera exposure time

The minimum exposure time of the industrial camera can determine the target's motion speed. Or conversely, the motion speed of the target places demands on the minimum exposure time of the camera.