According to related research reports, the image sensor market has been developing rapidly in the past year. The current unit shipments of the image sensor market will increase at an annual rate of 30%, which is mainly due to the rapid growth in shipments of digital cameras, camera phones and scanners. With the rapid improvement of image sensor technology, its applications are becoming more and more extensive.

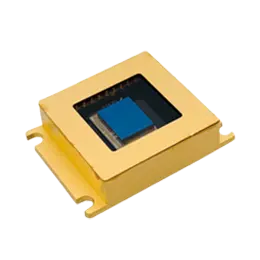

The image sensor is a device that uses the principle of photoelectric conversion to convert the optical signal of the image into an electrical signal. The traditional CCD image sensor technology is relatively mature, but the cost remains high due to the complexity of the process, which greatly limits its promotion and application. Therefore, the contact image sensor (CIS) was launched in the late 1980s. It is an array of sensor ICs made by CMOS technology. The length of the array is the same as that of the original. The light path is determined by the CIS body. With the characteristics of small size and short light path, the composed SWIR vision systems are also small in size, simple to install, and have no need to adjust the light path, which solves the problem in the uniformity of image optical signal and component volume, and facilitates the realization of product miniaturization.

The working principle of the contact image sensor is that with LED as the light source, the emitted light is uniformly irradiated to the surface of the original through the light guide, and the light signal carrying the image information is then focused on the surface of the sensor through the lens array. For A4 format 200DPI CIS, the total length is 1728 optical ports (sensor units), the distance between optical port and optical port is 0.125mm, and the illumination time (charge accumulation time) of each optical port in each reading cycle is the same. After the accumulation time is reached, the analog switches are controlled by the shift register to turn on sequentially, and the analog signals corresponding to the pixel information are sequentially output. Because the signal is weak, it must be amplified and zero-point corrected before being submitted to the signal processing circuit. If necessary, the analog signal can be converted into a digital signal for further processing.

Take a fax machine as an example. The connector type between the fax machine and the CIS is that the fax machine provides the working power VDD and VSS, clock CLK, strobe signal SI, light source voltage VLED and GLED to the CIS, and the CIS outputs the analogy signal SIG containing image information to the fax machine.

At present, more than 95% of fax machines have adopted contact image sensors as image reading components, and CIS can also be applied to scanners, currency detectors and train ticket sales systems, and can be used to scan various bills, card reading, etc. with the resolution that has reached 1200DPI. CIS was produced in the late 1980s and has been widely used in products such as fax machines. It is believed that with the advancement of technology, contact image sensors will have a broader space for development.