In high temperature manufacturing, some special processes, such as metal processing and welding, occur in furnaces or envIRonmental chambers designed to maintain specific atmospheric conditions. These chambers generally have windows made of ordinary silicon-based glass, which are opaque at longer wavelengths. The current solution is to install windows made of materials such as zinc selenide or calcium fluoride in these chambers to be transparent to long-wave infrared or millimeter-wave infrared. However, these materials are not only more expensive than silicon-based glass, but they may not be able to handle the envIRonmental conditions of the chamber (such as heat, humidity, or vacuum) exactly like glass.

Another issue to consider is that the heat energy released by the material may vary. This change not only occurs between different materials, but also occurs between the same material at different temperatures or different processing stages. These changes in emissivity will affect the accuracy of temperature measurement, and this effect is more pronounced at longer wavelengths than at shorter wavelengths.

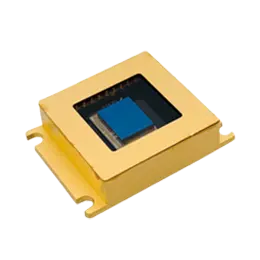

In recent years, short-wave infrared imaging technology (SWIR technology) has become more mature, and the response wavelength of short wave IR camera is 0.9 to 1.7um. Previously, they were only used for qualitative imaging applications, such as laser beam profiling, silicon wafer inspection, and imaging through paint/ink layers, rather than for actual quantitative temperature measurement applications. Now, with the increase of temperature measurement function, coupled with short wave IR camera can easily penetrate the glass for observation, and in the case of emissivity changes, it can also accurately measure the temperature.

The expansion of temperature measurement function of short wave IR camera can provide solutions for customers who care about high temperature material or process thermal analysis.

In metal processing operations, the temperature during material processing is very important. For example, to manufacture steel plates, manufacturers start with a piece of molten metal and roll it back and forth on a rolling mill to achieve the requIRed thickness. Throughout the process, steel needs to maintain a certain temperature. The reason is that compression at a too low temperature will change its material properties, resulting in the production of substandard steel.

3D printing technology is another process that requires high temperature consistency. One way of working in 3D printing is to deposit a metal powder first. Then use a laser to quickly heat the powder, melt and fuse it into a solid. Like traditional steel manufacturing, the temperature of material processing will affect its final performance.

In these applications, the temperature measurement of each process is very important for those processes that require very high consistency. Using a short wave IR camera after temperature calibration, users can obtain the complete thermal profile of the product. Since it can measure temperatures up to 3000°C, there is no need to worry about missing the critical temperature threshold.